Cha Yau Enterprise Co., Ltd. is currently the largest manufacturer of EVA foam mats, sports mats, and related foam products in Taiwan.

With the growing demand and expanding market for EVA products, the factory has continued to receive increasing orders. Inevitably, this results in larger amounts of production scrap. As is well known, EVA waste is extremely difficult to recycle. The chemical substances contained in EVA, if not properly treated, may trigger peroxide reactions during subsequent processing, which could lead to serious risks.

Moreover, the proportion of recycled EVA pellets that can be reused in standard foaming formulations is very low. As a result, recycled EVA materials have never been widely adopted in large-scale production. This has long made EVA scrap a serious burden for EVA foam manufacturers.

Traditionally, factories have had no choice but to spend significant sums each month to entrust environmental recycling companies to handle EVA waste. This not only increases costs but also places pressure on the environment. In recent years, Taiwan’s environmental regulations have become increasingly strict. Recycling fees continue to rise, and in some cases recycling companies even refuse to accept EVA waste. Consequently, EVA scrap has become a major obstacle that prevents factories from taking on larger orders and hinders industry growth.

In light of these challenges, Chairman Mr. Kao Yung-Hsin and Factory Director Mr. Kao Chien-Chuan began exploring solutions in 2017 to convert EVA production scrap into usable recycled material. After years of relentless research and testing, by the end of 2020 they successfully developed a method to completely remove the residual chemicals contained in EVA waste.

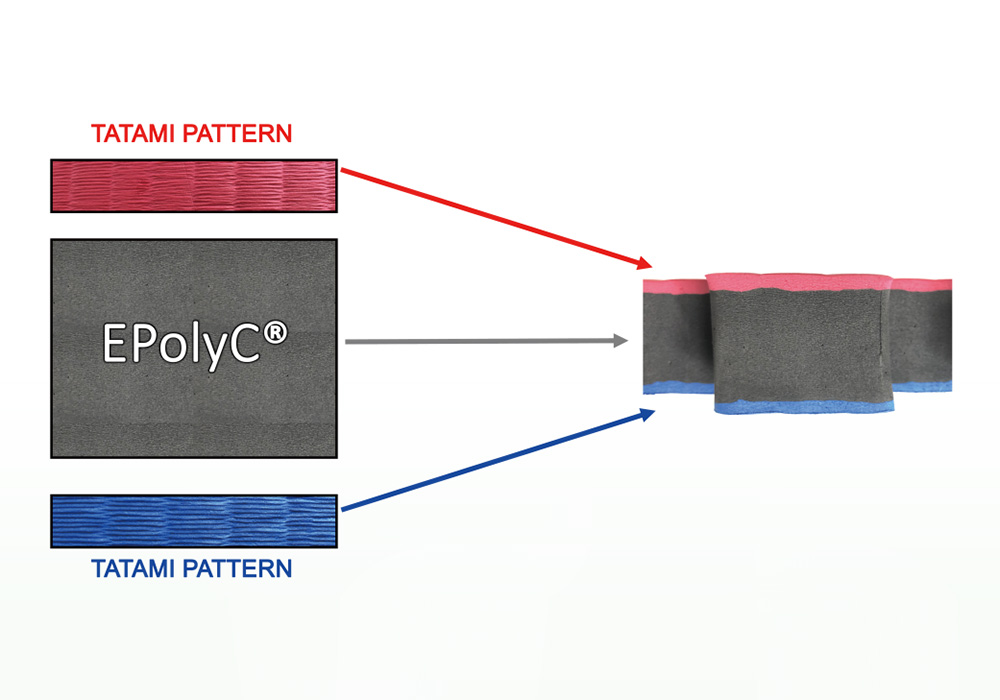

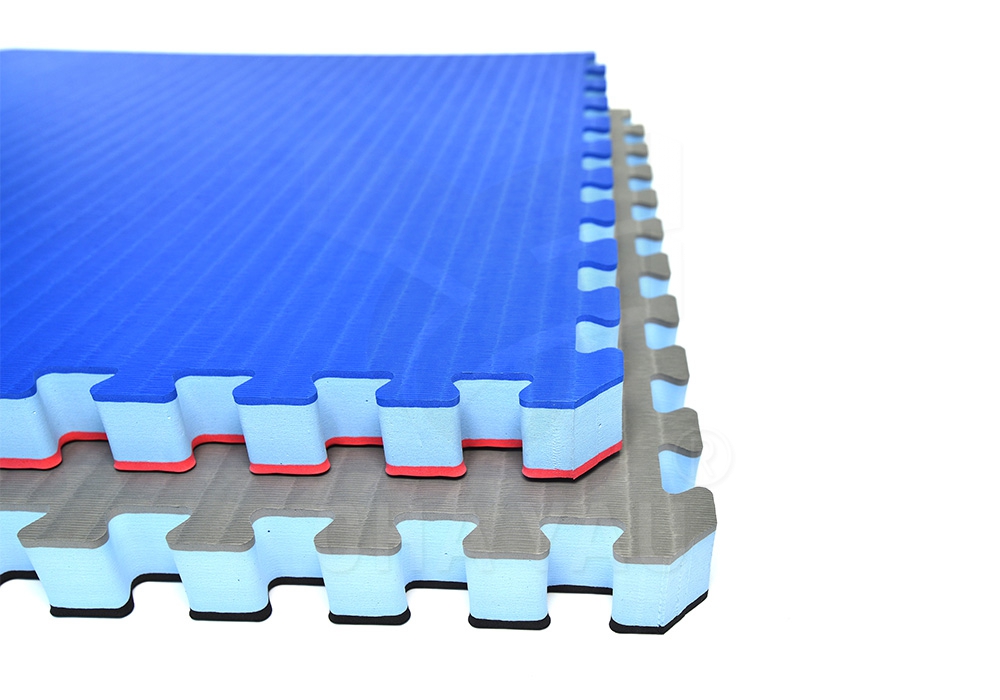

Through this breakthrough, Cha Yau created a new recycled material – EPolyC®, which can be safely incorporated into standard EVA formulations. By upgrading production formulas and improving process technology, Cha Yau has significantly increased the usability of EPolyC®, with applications now reaching up to 50% content in foam mats.

In addition, when EPolyC® is used as a partial substitute for traditional fillers, it not only enhances the physical properties of the mats but also ensures cost efficiency. Moreover, mats produced with EPolyC® have successfully passed the stringent European EN-71 safety standard, demonstrating excellent quality and strong competitiveness in the global market.

Advantages of Mats Made with EPolyC®:

- EPolyC® material certified by REACH

- Mats produced with EPolyC® certified by EN71

- Manufactured with Cha Yau’s latest formulation technology

- Maintains Cha Yau’s consistent high quality standards

- Enhanced physical properties

- More competitive pricing

Cha Yau Enterprise Co., Ltd., as a pioneer and industry leader among Taiwan’s EVA foam mat manufacturers, has developed a safe and reliable recycled EVA pellet. This material can be added in large proportions to enhance product strength. The primary purpose is to contribute to environmental protection in Taiwan, safeguard the well-being of future generations, and fulfill our corporate social responsibility, while also enabling the sustainable development of Taiwan’s EVA industry.

Cha Yau will continue to pursue innovation and research, creating new value from EVA waste through recycling. Looking ahead, we are committed to further advancing our production technologies, ensuring that as Cha Yau connects with the global market, we maintain our unique strengths and international competitiveness, remaining at the forefront of the EVA foam industry